You deserve to have access to the most advanced dehydrators

CanDry Helps to Grow Your Business Using our Patented and Innovative Low-Temperature Drying Technology

CanDryTM reduces dehydration time, improves energy efficiency, and allows for easy scalability. With a compact design and user-friendly interface, CanDry machines are easy to operate and integrate seamlessly into existing production processes. Experience the future of dehydration with CanDry and unlock the full potential of your products.

About us

CanDryTM low-temperature drying technology produces superior products faster and more affordable!

$1-$3

Thermal Drying

Drying time: 6-12 hours

Temperature: 80-150 C

Nutrition loss: 60%-80%

Footprint: 300-400 ft2

Fossil fuel

$5-$10

1st Generation Microwave Drying

Drying time: 80-120 mins

Temperature: 40-60 C

Nutrition : <10%

Footprint: 400-500 ft2

Electrified

$2-$3

CanDry Drying

Drying time: 40-90 mins

Temperature: 35-37 C

Nutrition : <3%

Footprint: 150-200 ft2

Electrified

$6-$10

Freeze Drying

Drying time: 12-72 hours

Temperature: -30 C

Nutrition : <2%

Footprint: 600-800 ft2

Electrified

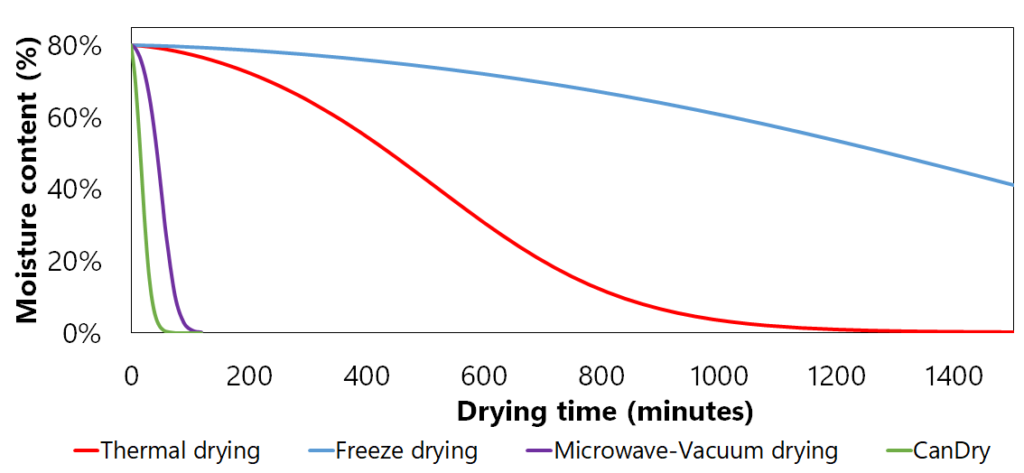

CanDry made it even faster

The current microwave-vacuum dehydrators in the market accelerated the drying process substantially. CanDry made it even faster! CanDry technology is more than 90% faster than thermal and freeze dryers and more than 25% faster than the 1st generation of microwave-vacuum dryers in the market. But, it is not our main benefit, scroll down to know more!

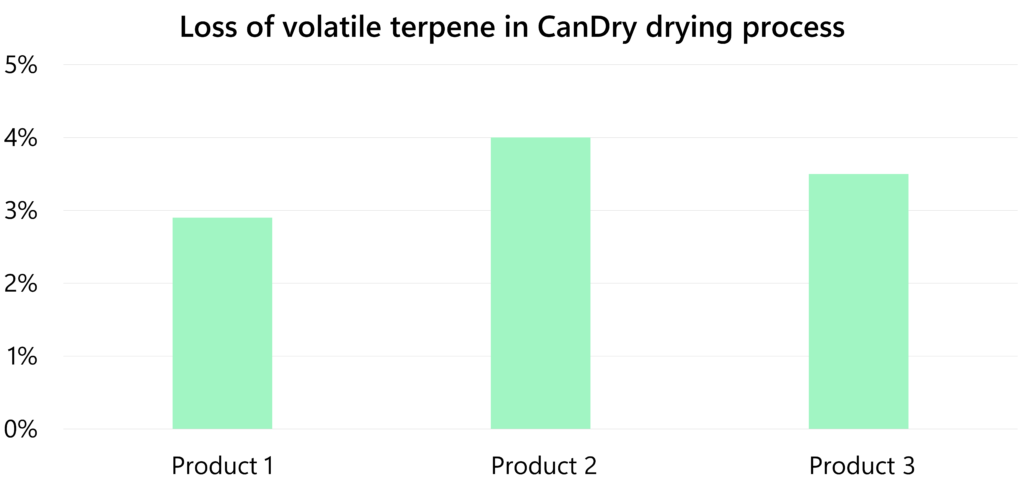

Looking to keep all valuable components of your food?

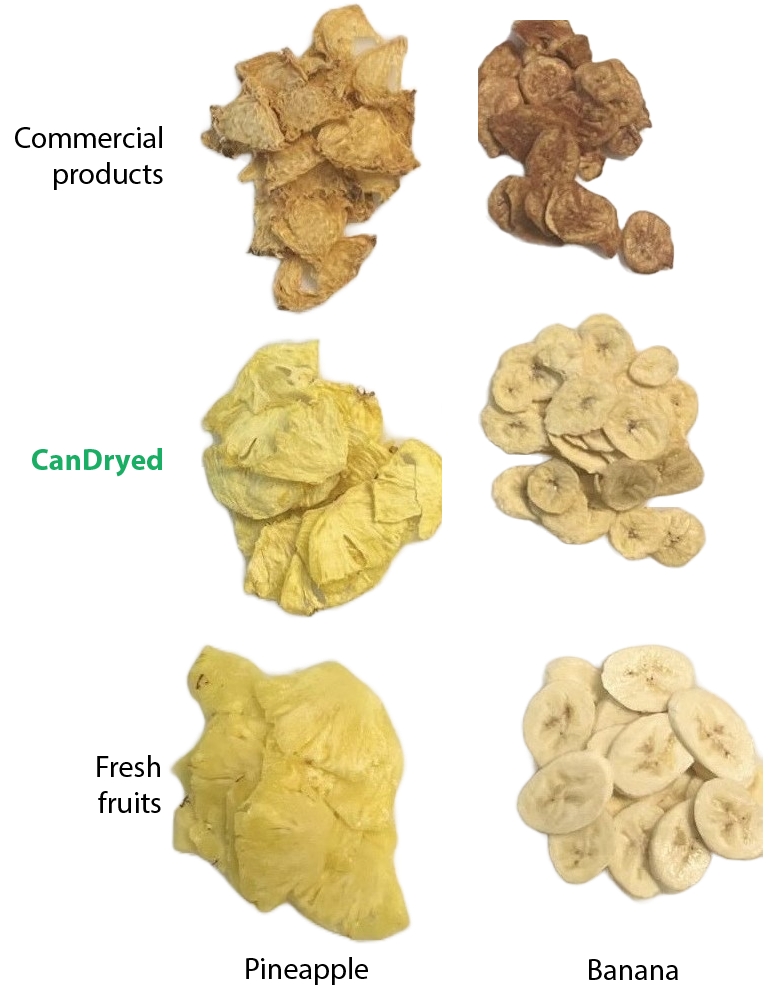

CanDry preserves 95+% of the valuable nutrients and pigments!

CanDry’s dehydration technology ensures superior nutrition preservation in dried products. By combining microwave and infrared drying methods, it retains essential nutrients, vitamins, and flavors, delivering nutrient-rich end products that appeal to health-conscious consumers.

CanDry dehydrates at the level of human body temperature

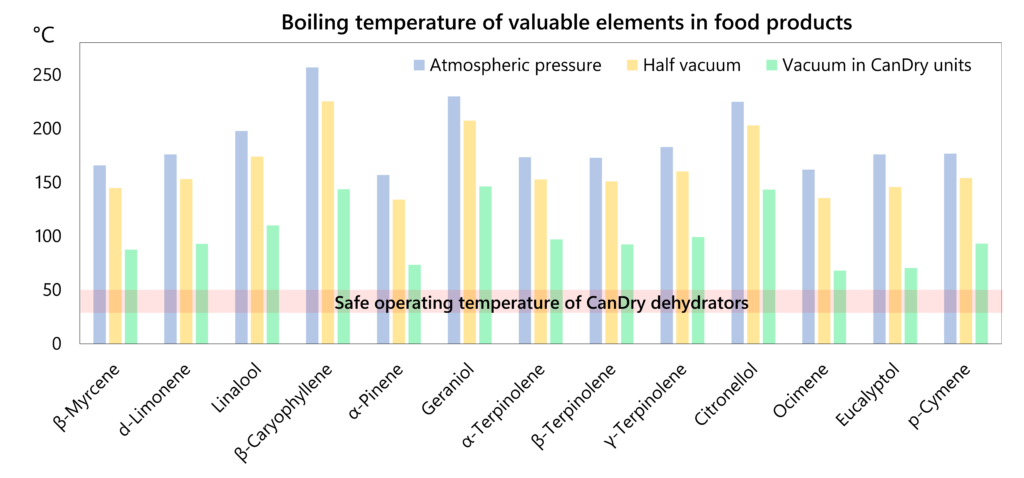

The key is “low-temperature” drying!

CanDry utilizes a low-temperature drying approach to preserve the quality and nutritional value of the dried products. By drying at low temperatures, CanDry minimizes heat damage and reduces the risk of nutrient loss, ensuring that the dried products retain their natural flavors, colors, and essential nutrients. This gentle drying process is especially beneficial for thermal and oxygen-sensitive materials, as it helps maintain their integrity and extends their shelf life. Additionally, low temperature drying contributes to energy efficiency and cost savings by reducing the amount of heat required during the drying process. With CanDry’s low-temperature drying technology, businesses can achieve superior drying results while prioritizing product quality and sustainability.

Our Commercial Dehydrators

You will get the same core patented technology in all our machines

Not everybody needs a large machine

Our pilot drying machine is perfect for both production and R&D

Full of monitoring sensory instruments

Full manual control on your process

Perfect fit for product development

Fully mobile machine

We have tested our technology with dozens of products, tell us what else you want to test.

Our small machine is an absolutely amazing tool to help you develop new products for your business and brand, with the help of phenomenal sensory instruments to monitor your product during the process.

We monitor temperature and moisture of the product every second during the process. Our control system knows what the next step is to ensure there is no temperature overshoot!

With customizable settings and a user-friendly interface, operators have full control over the drying process, and you will get the same quick, affordable, and nutritious drying process as you get in our commercial machine!

It is also a perfect choice for a small-scale production. Our small machine easily processes 10-20 kg of your product in each cycle. CanDry will customize it to meet your specific needs.

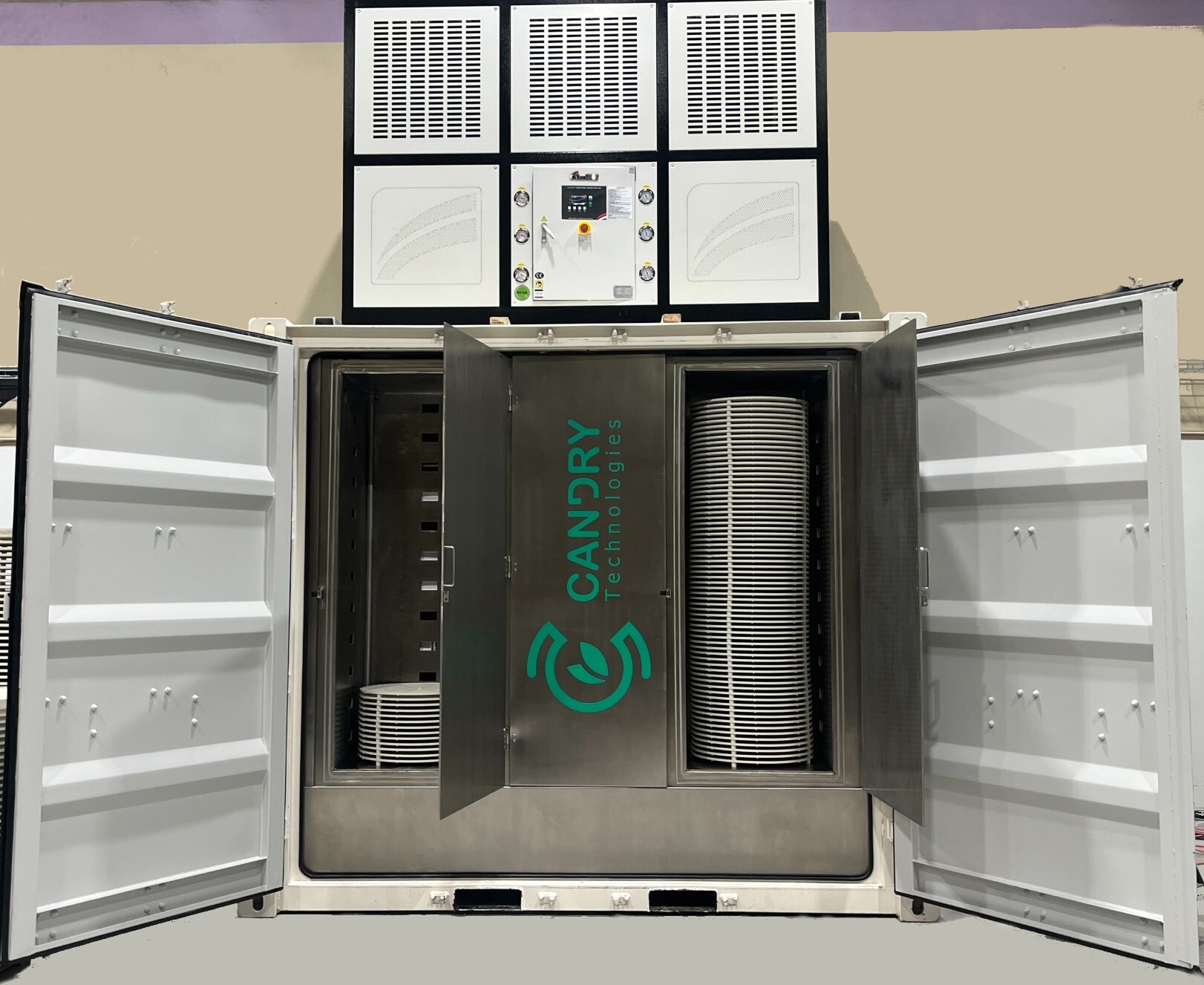

Our commercial machine is a portable drying room nobody else can compete with!

Consistent capacity

Whether it’s fruits, vegetables, or other sensitive materials, CanDry customizes the technology to let you always operate at maximum capacity. It guarantees your success with minimizing the operating cost.

Short cycles

Each cycle takes 1 hour for tough products like fruits and 30 minutes for easy products like mushrooms and grains.

Portable

It comes all in one portable shipping containers. This approach allows for easy transportation and installation of the dehydration system, providing flexibility and convenience to users.

kg per shift

kilowatt

Savie drying cost

Smaller footprint